Two years ago, I carried out a coup-d'état, and claimed the front room of our appartment as a workspace. Up until that time, neither my wife or I knew what to do with it. It's a nice space with bay windows, but the front door always made the space seem too awkward to be used as a living room. So for years, it was pretty much an entrance space, passed through, but not lived in. Two years ago, I was craving a hands-on project and decided to scratch build a foam board RC plane. Since then my interests have expanded into woodworking, digital fabrication, and "making" in general.

Recently, it became clear that I needed to address the chaos that emerged as soon as I worked on something in the front room of our appartment. Over the last two years, I have accumulated a number of tools and materials that seems to indicate a degree of dedication, so I thought it was worth trying to improve my setup. In addition, as mentioned in the previous post, I needed to build an enclosure for the X-Carve to reduce the soundlevels and to contain the dust. For the latter problem, I'll also be installing a dust shoe.

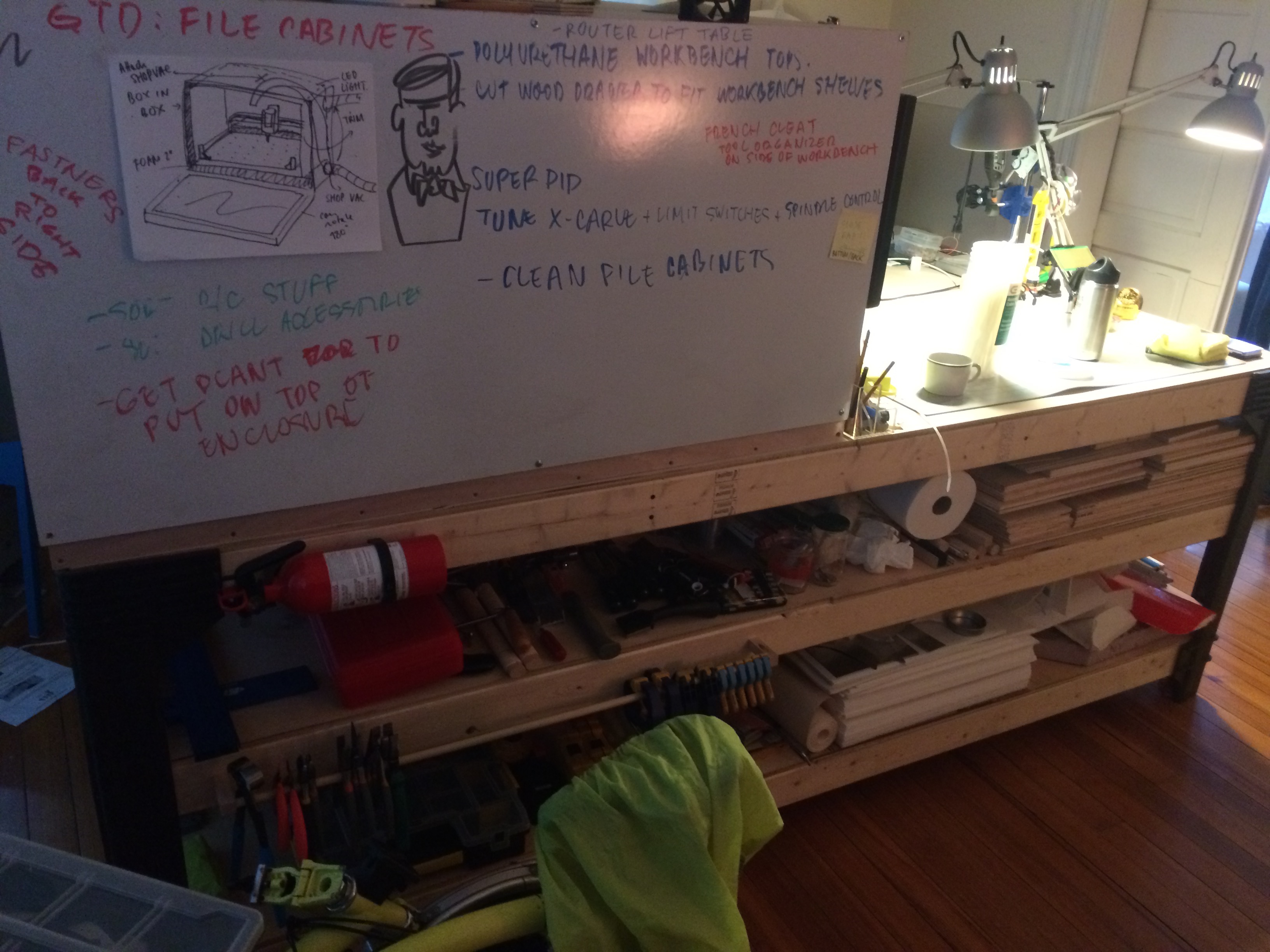

I saw Winston Moy's workbench and decided to get the same injection-moulded 2x4basics kit. I intalled all three tiers and used full 1/2" birch plywood 4'x8' sheets (1.22m x 2.44m). Half of the top tier work surface is occuped by my X-Carve enclosure. The enclosure is a box made out of 3/4" plywood (approx. 4'x2'x2'). The front is open for now, as I'm quite convinced the soundproofing at this point is minimal anyway. I'll need more research to find out what to do.

The enclosure is huge, but I had some ideas that will hopefully console me for all the working area I've lost:

Some updates I've carried out:

- The workbench facing side of the enclosure hosts a 27" monitor and 2nd generation apple TV. This allows me to airplay youtube videos, use it wirelessly as an external monitor, easily show my screen to the person sitting on the other side of the workbench, or just watch a movie on netflix.

- I've mounted a Nest smoke/CO2 detector. Since the CNC router and other tools pose a fire hazard I wanted a device that could send me a push notification if anything went awry.

- I've installed two 9 outlet surge protected powerstrips, this should prevent me from running out of outlets for at least two weeks.

- A small fire extinguisher was mounted near the X-Carve.

- I got a mogo seat. Space is at a premium and it is easy to get out of the way.

- Protected the workbench top with Minwax Polycrylic.

- Mounted the dowel with pliers and mini clamps (photo above) onto a french cleat, so I can move it around.