I got interested in the Glowforge laser cutter and placed a pre-order for their pro machine. However, I ended up cancelling order last sunday, and decided to buy a CNC machine instead.

The narrow kerf and speed of a lasercutter is nice for some applications, but I realized I'd have more use for a CNC. The CNC will allow me to an even wider range of materials, including: wood, plywood, plastics, linoleum, wax, brass and aluminum. I'll be able to cut through much thicker materials, not only can I cut profiles and pockets, I can create curved surfaces, I can mill printed circuit boards and prototype furniture. I can cut 2.5D instead of 2D: allowing me to cut curved surfaces. In addition, the glowforge is still under development, so it's a lot of money to have invested in something that nobody has actually reviewed yet.

So, I bought the X-carve from Inventables (large model 1000mm, fully loaded + 1/8" collet). Inventables has been pretty agressive in the marketing of their machine: it seems that they sent one to every woodworker with more than a hundred viewers on youtube, so there are plenty of reviews. The Shapeoko 3 seemed interesting with its sturdier rails, but the lack of reviews and smaller bedsize made me go with the x-carve.

The main complaint about the X-Carve seemed to be that the spindle was underpowered, but they are now shipping it with a DeWalt 611 router, which people seem to be pleased with.

The machine is fully consists of Open Source components, meaning it is fully customizable, both hardware and software. I can swap out any component for a different one, if I so desire. In addition, it's about half the price of the Glowforge Pro, even with the inclusion of VCarve Pro software

The working area is large (80cmx80cm) and offers a lot of possibilities. Of course, it's not sufficient for large pieces of furniture, but what's really great is that I can create scale models at home, iterate and improve them, and proceed to go cut them on the 4'x8' ShopBot CNC router at AS220 at full scale.

At AS220 they also have use VCarve Pro software on the computer attached to the CNC, which I also bought to use with the XCarve, so that should feel nice and familiar.

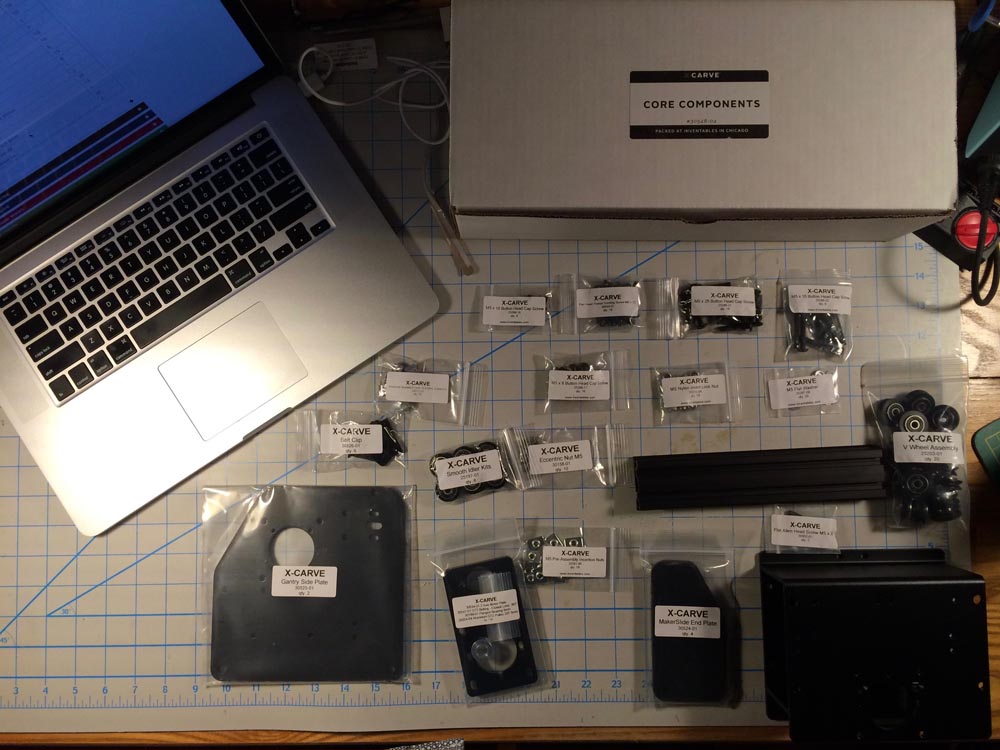

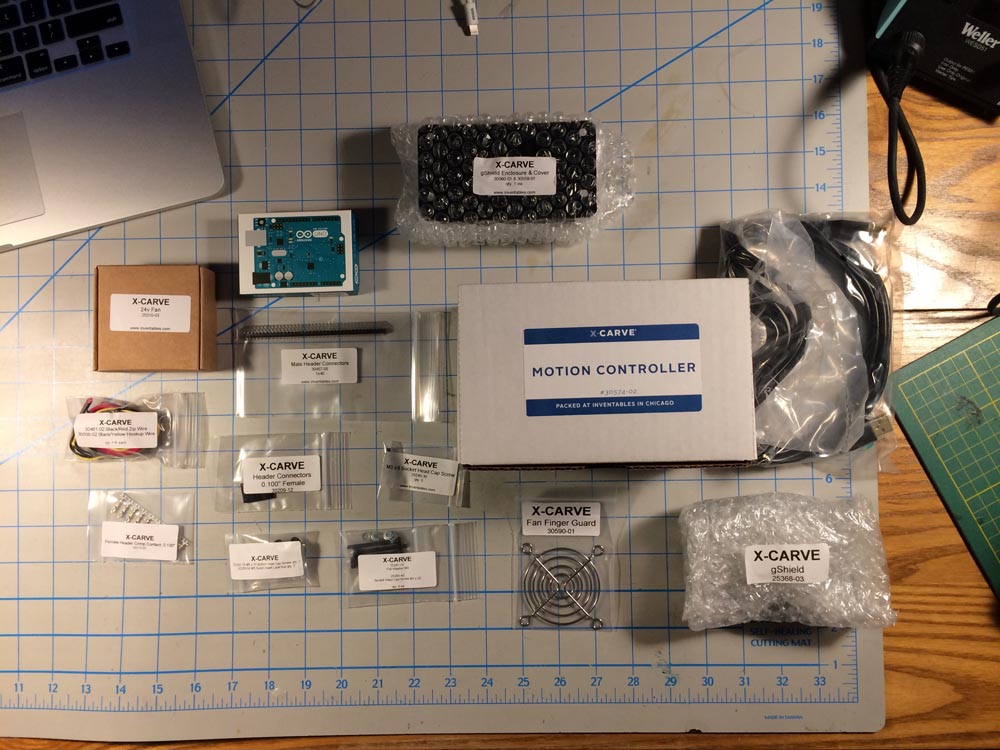

When you order an XCarve, you just get the components (box above excludes aluminum makerslides, aluminum extrusions and wasteboard), all the assembly and wiring up and setup needs to happen. It's a lengthy process, but it gives you an understanding of how the machine works, and gives me confidence in troubleshooting when something goes awry later on. Also, it saves on money, this machine would be much more expensive if it came assembled.

The DeWalt 611 spindle is backordered and should be sent out on the 25th. UPS delayed the wasteboard delivery, and it turned out--as I was going over the bill of materials--that I was missing a few connectors that should have been in the shipment.

- 25306-02 Terminal Block 2C 3.5mm Plug

- 25306-04 Terminal Block 4C 5mm Plug

Let's see if Inventables gets them in with my spindle shipment.

I'm thinking about building a table/enclosure to contain the dust and reduce the noise. Below the CNC I would like storage space. This article seems like it provides a good starting point, but silencing the shop vac whilst providing adequate cooling might be tricky.

Here are photos of the contents of each kit: